A Just In Time Inventory System Usually Reduces Costs For

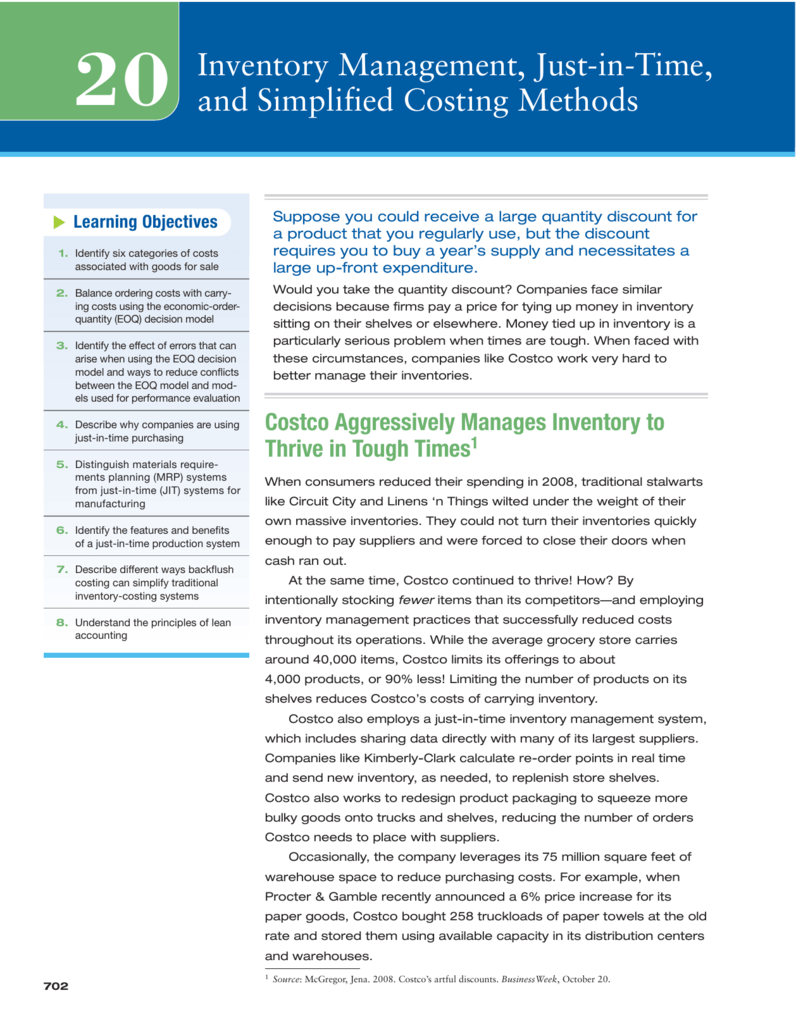

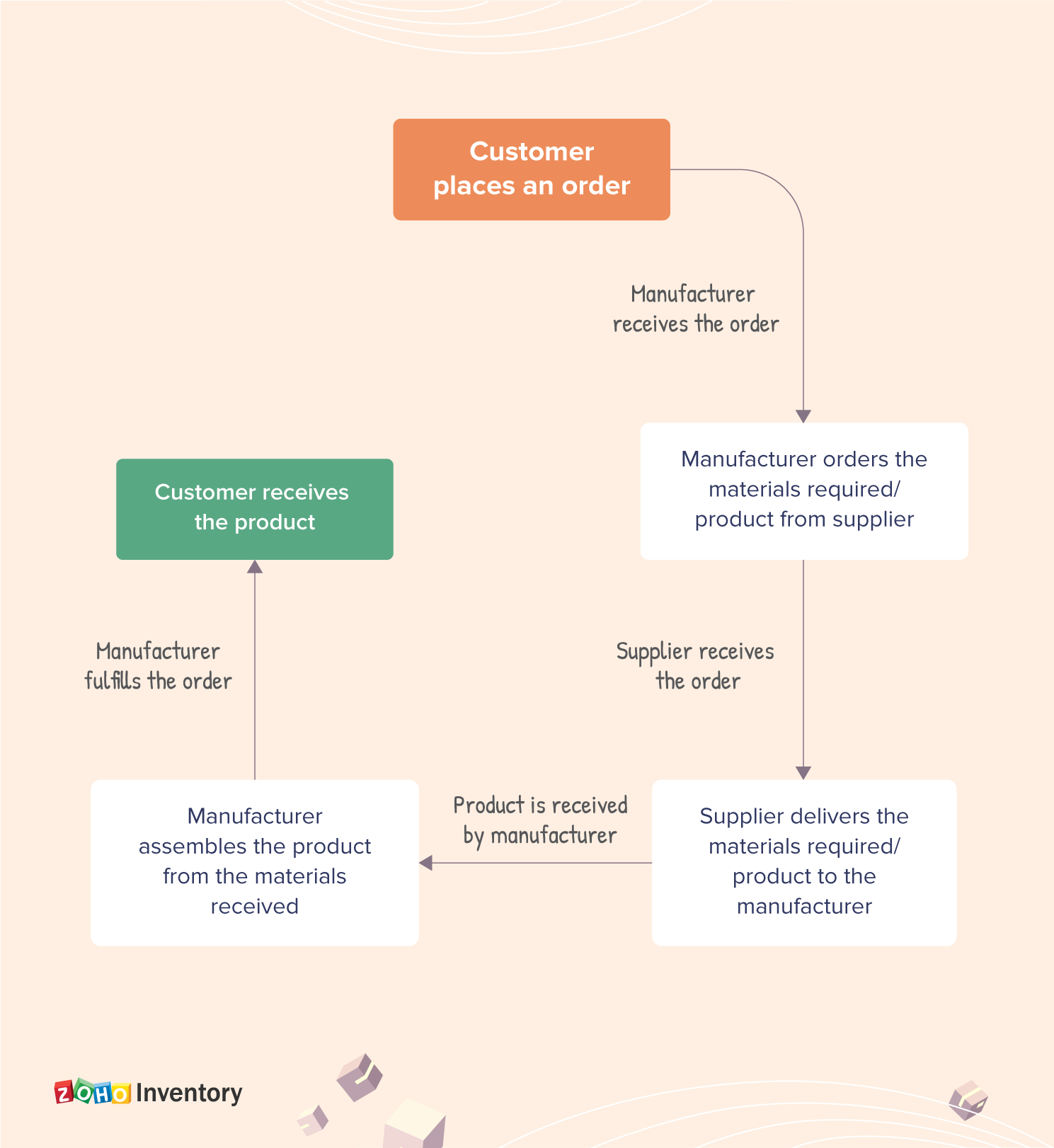

A just in time inventory system usually reduces costs for. Just in time inventory offers businesses a chance to streamline their purchasing ensure a steady stream of supplies and keep inventory costs low. However the supplier must deliver the needed materials and parts just in time to be used in the production process. Accountancy 25082019 1800 tegery.

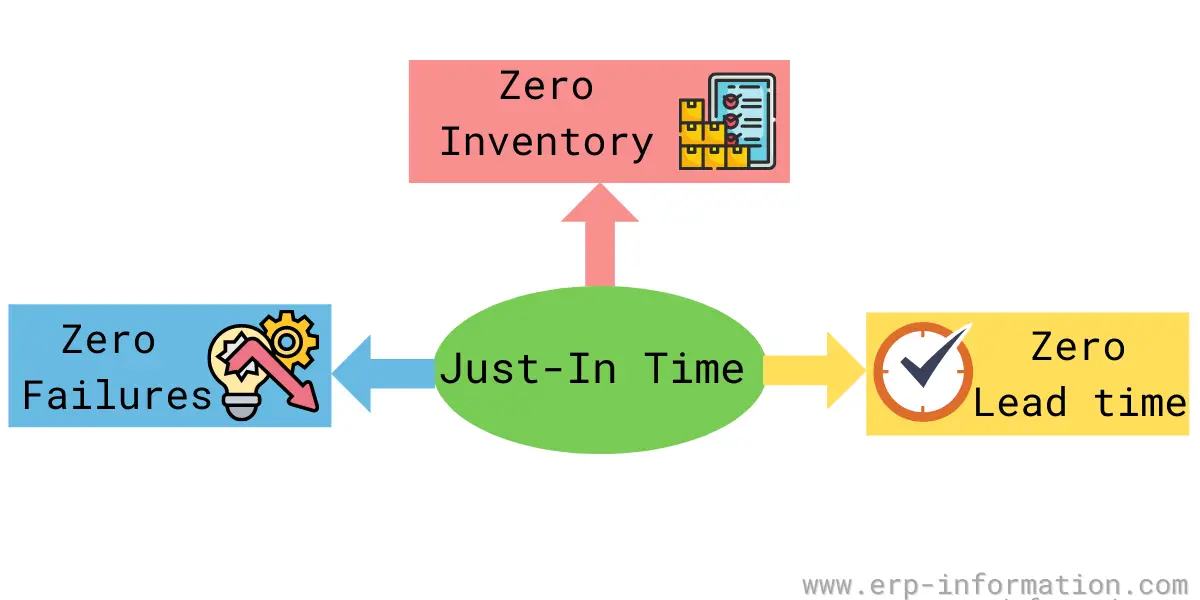

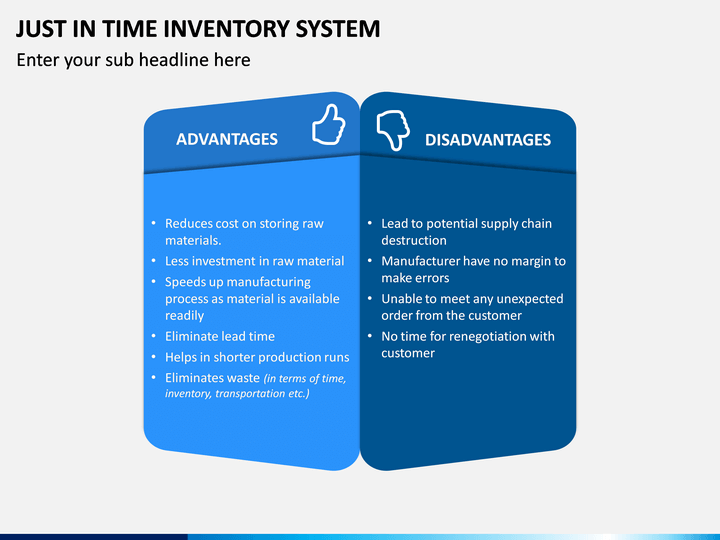

Just-in-time inventory systems allow producers to reduce the amount of inventory they hold thus keeping their inventory costs down. In a just-in-time inventory system there is less emphasis on the need to eliminate scrap and rework problems. Leverage your professional network and get hired.

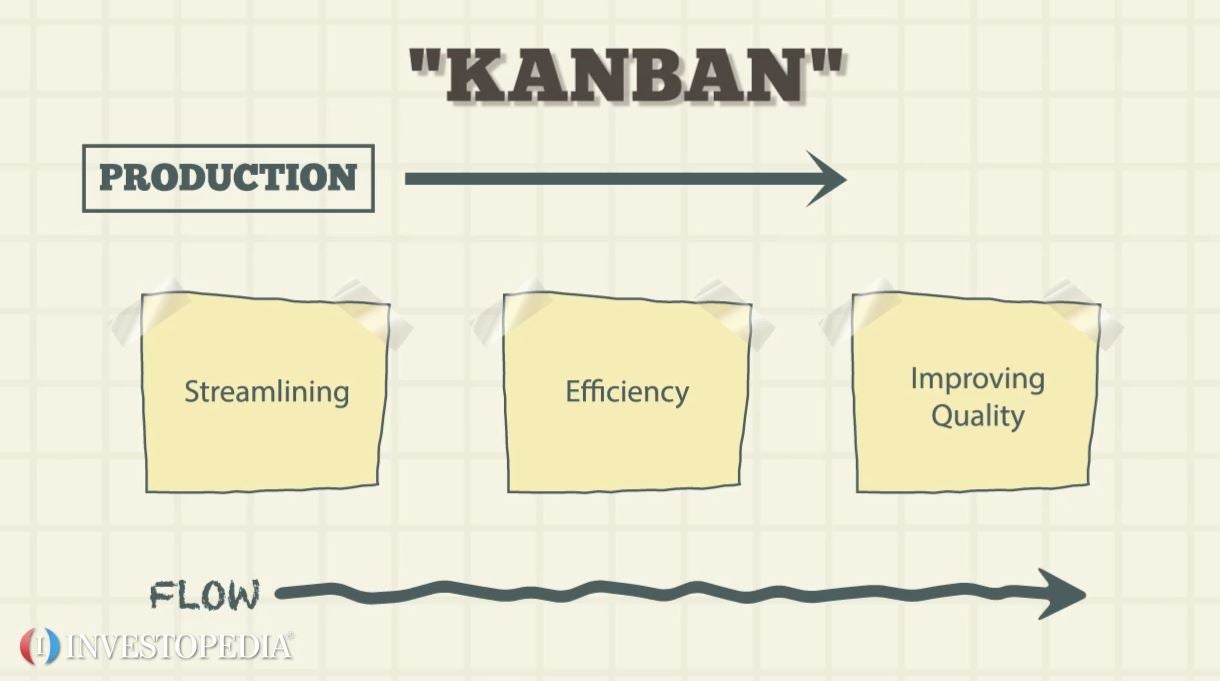

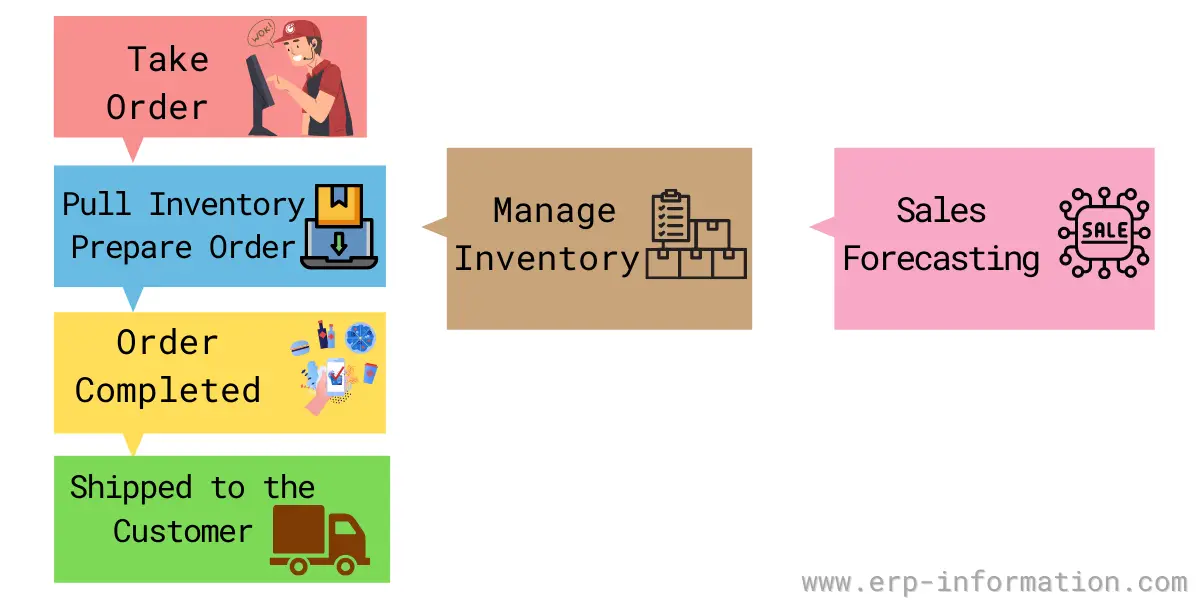

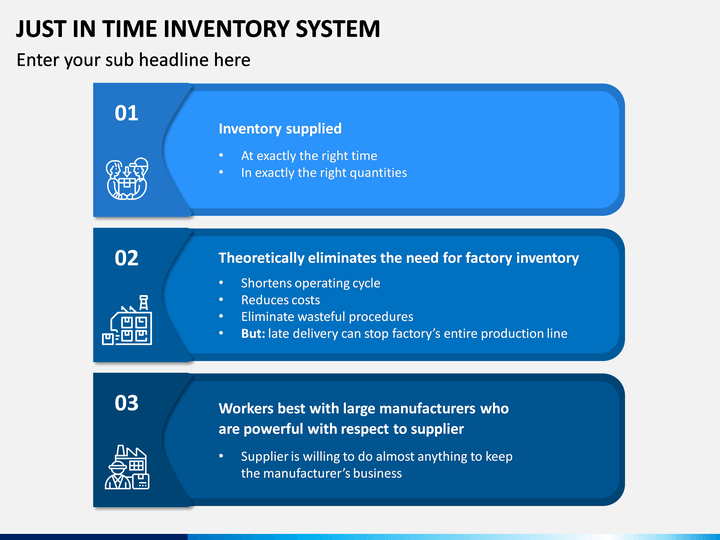

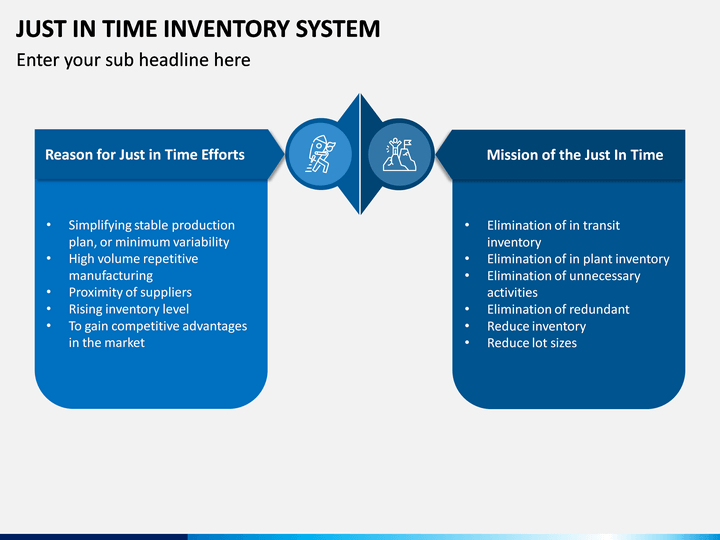

Companies employ this inventory strategy to increase efficiency and decrease waste by receiving goods only as they need them for the production process which reduces inventory costs. Overhead costs are also reduced as there is no need to. Just-in-Time is a great way to minimize inventory costs and space while improving responsiveness and flexibility.

The just-in-time inventory model lets manufacturers reduce their overhead expenses while always ensuring that parts are available to manufacture their products. B usually increase PD costs for suppliers. A just-in-time inventory system usually reduces costs for.

Here are some of the benefits of using Just-In-Time Inventory Management. This allows a companys customers to be better served while at the same time lowering the cost of doing business. Ajust-in-time inventory system usually reduces costs for.

C usually shift less responsibility for PD to business customers. However the supplier must deliver the needed materials and parts just in time to be used in the production process. Understanding Just In Time Inventory By Steve Syverson January 3 2021 Read Time.

A just-in-time inventory system usually reduces costs for. 1 Get Other questions on the subject.

Since excess inventory is never purchased inventory costs are reduced.

A just-in-time inventory system usually reduces costs for inventory. Todays top 10 high paying Job roles. A financial benefit of a just-in-time system is that inventory carrying costs are reduced. Just-in-Time is a great way to minimize inventory costs and space while improving responsiveness and flexibility. A just-in-time inventory system usually reduces costs for. The just-in-time JIT inventory system is a management strategy that aligns raw-material orders from suppliers directly with production schedules. The small size reduces in-process inventory carrying costs storage space and makes for easier inspection and rework. Accountancy 25082019 1800 tegery. Also it renders many benefits.

In JIT one is the ideal lot size. Overhead costs are also reduced as there is no need to. Thats why many companies have adopted the Just In Time inventory model. C usually shift less responsibility for PD to business customers. Small Lot Size. Companies employ this inventory strategy to increase efficiency and decrease waste by receiving goods only as they need them for the production process which reduces inventory costs. Explain the meaning and objective of trial balance.

.jpg)

.jpg)

.jpg)

/GettyImages-626175462-7bca4544ff444d39b4f166994f29523a.jpg)

/inventory-291c7c3c45a74e0a94c3708742e48ff9.jpg)

Post a Comment for "A Just In Time Inventory System Usually Reduces Costs For"